08 Oct Innovative Drilling Technology Could Help the Industry Through Recent Tough Times

Master Drilling is one of the largest providers of oil and gas drilling equipment and services including exploration-stage, capital project-stage, and production stage drilling. Through their services the South African-based company has helped grow the global proved oil reserves by 27% (over 350 billion barrels) over the past decade. They’re also one of the only companies in the business making significant profits during the recent industry slump.

One of the primary ways they’ve been able to stay in the green is because of their specialty in helping other companies with horizontal drill boring solutions. According to the South African economic and business news site BDLive.co.za, the company is close to releasing their newest technologies that could be a game-changer for underground workers, by raising productivity and reducing costs.

With the current struggles due to low demand and excess supply the mining, oil, and drilling industries are faced with, any type of advancement to help businesses become more efficient would be highly desirable. There are currently enough crude oil reserves for 53 years of global production, but new innovations like this can keep that number rising.

They don’t expect to be able to officially release the new technologies before the end of the year, but one of their first key testing applications will be at drilling a tunnel on an inclined gold reef at the Sibanye Gold’s Kloof mine. Danie Pretorius, Master Drilling’s CEO, believes the processes in the works could benefit the entire industry.

“Any equipment you bring to a mine to open reserves can only add value. Whatever you do with a non-drill and blast system that has speed and efficiency will make a huge difference,” Pretorius said. “We were told last week that most mines in the world run at between 50% and 70% capacity. Isn’t that suicide? We are saying if that’s true, why not deploy a way to open reserves more quickly.”

The horizontal bore which they’re developing weighs a fraction of the weight of an average tunnel borer and is capable of drilling 300 meters in six months. The same project would take two to three years to complete using explosives and hand-held drills.

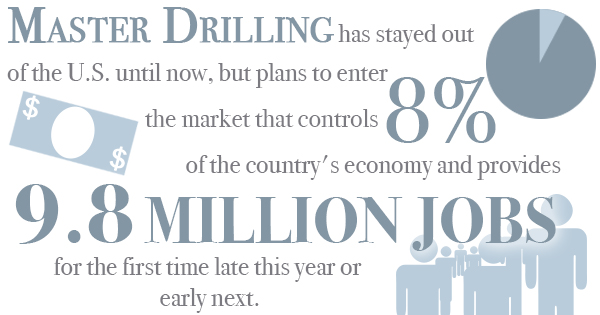

Master Drilling has stayed out of the U.S. until now, but plans to enter the market that controls 8% of the country’s economy and provides 9.8 million jobs for the first time late this year or early next. Their hope is their new technologies can help boost the once booming market. The technology might have been developed with the African terrain in mind, but Pretorius believes it can be utilized around the world.

“For regions like Africa, this technology is vital. I really believe there is scope for it. We want to adapt the blind hole machines used in the U.S. and China to be hard-rock machines,” he said.

Sorry, the comment form is closed at this time.