07 Dec A Beginner’s Guide to Oil Drilling Equipment in the Oil & Gas Industry

The driving force behind this thriving industry is the oil drilling equipment used to extract crude oil and petroleum from the earth. But do you know all there is to know about oil drill rigs and tools?

Being well-versed in the different types of oil drill equipment is important for oil and gas industry professionals, who must make informed decisions, optimize performance, and maintain safety standards in their operations.

This guide provides an overview of essential oil drilling tools and equipment, their functions, and how Dragon Products can support your worksite with the right oil drill rig and other hard-working products you need to get 'er done.

IN THIS ARTICLE

Employment in the Oil and Gas Industry

The oil and gas industry currently employs nearly 11 million Americans, and contributes significantly to the U.S. economy. This figure includes direct employment in oil and gas companies as well as jobs in the industry supply chain, supported by the sector's operational and capital spending. The industry's economic impact extends beyond energy production, influencing various facets of the economy and providing millions of jobs nationwide. The industry contributes almost $2 trillion to the U.S. GDP, highlighting its significant economic impact.

Economic Contribution and Oil Reserves

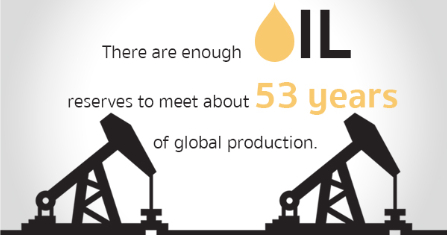

The oil and gas industry is a substantial part of the U.S. economy, making up approximately 8% of the GDP. Due to the steady increase in global oil reserves, this sector's influence is projected to remain robust.

Over the past decade, proven global oil reserves have grown by 27%. Per the BP Statistical Review of World Energy and other industry analyses, these reserves are sufficient to support worldwide oil production for approximately 53.3 years.

These updated statistics reflect the ongoing importance and growth of the gas and oil sector in the U.S. and globally.

Types of Oil Drilling Equipment

These components form the backbone of drilling operations, ensuring efficiency, safety, and productivity in extracting oil from the earth.

Oil Drill Rigs

Oil drill rigs house the equipment needed to drill wells and extract oil. There are various oil drill rigs, including land, offshore, and mobile rigs, each designed for specific environments and drilling requirements.

- Land Rigs: The most common type of oil drill rigs, these are used for onshore drilling and can be adapted for different drilling depths and conditions.

- Offshore Rigs: These rigs operate in ocean waters and include submersible rigs, jack-up rigs, and drillships. Offshore rigs are made to withstand harsh marine environments and extract oil from beneath the seabed.

- Mobile Rigs: Also known as portable rigs, these can be moved easily to different drilling sites, making them ideal for exploratory drilling and remote locations.

Oil Drilling Tools

Oil drilling tools are critical for the success of the drilling operation. They include:

- Drill Bits: The cutting tools attached to the drill string that break up rock and soil to create the wellbore.

- Drill String: A series of connected drill pipes that transmit drilling fluid and torque to the drill bit.

- Blowout Preventer (BOP): A safety device that will prevent the accidental release of crude oil or natural gas from the well.

Oil Rig Parts

Understanding the parts of an oil rig is crucial for efficient operation and maintenance. Key parts include:

- Derrick: Also called a drill mast, this tall structure supports the drill string.

- Mud Pump: Circulates drilling fluid (mud) to cool down the drill bit and extract cuttings from the wellbore.

- Power System: Provides the energy needed to operate the rig, including generators and engines.

- Rotary Table: A turntable that rotates the drill string and drill bit.

- Centrifuge: Separates drilling fluids from solids to maintain the proper consistency and density of the drilling mud, ensuring efficient drilling operations.

- Drawworks: A hoisting mechanism on the drilling rig that controls the lowering and lifting of the drill string, facilitating the drilling process.

- Drill Bit: The cutting tool positioned at the end of the drill string used to break up rock and soil to create the wellbore.

- Drill Pipe: A hollow, steel pipe that transmits drilling fluid and torque from the surface to the drill bit, enabling deep drilling operations.

- Kelly Drive: A section of the drill pipe that's square or hexagonal, providing the mechanism for rotating the drill string.

- Mud Tank: A large container that stores drilling fluid (mud) and circulates through the wellbore, cooling the drill bit and carrying cuttings to the surface.

- Swivel: A mechanical device that allows the drill string to rotate while maintaining a fluid-tight seal, enabling the circulation of drilling fluid.

- Top Drive: A motorized device that provides rotational force to the drill string from the top, enhancing drilling efficiency and safety by eliminating the need for a rotary table.

Oil and Gas Production Equipment

Once the oil is extracted, it requires further processing and handling. Essential oil and gas production equipment includes:

- Separators: Devices that separate oil, gas, and water from the production stream.

- Storage Tanks: Store crude oil before it's transported to refineries.

- Pipelines: Transport oil and gas from the well site to processing facilities and markets.

Why Choose Dragon Products?

Dragon Products is a leader in the manufacturing of high-quality oil drilling equipment. Our products meet the demands of the oil and gas industry, ensuring efficiency, safety, and reliability. From advanced oil drill rigs to essential oil drilling tools, Dragon Products offers a comprehensive range of equipment tailored to your needs.

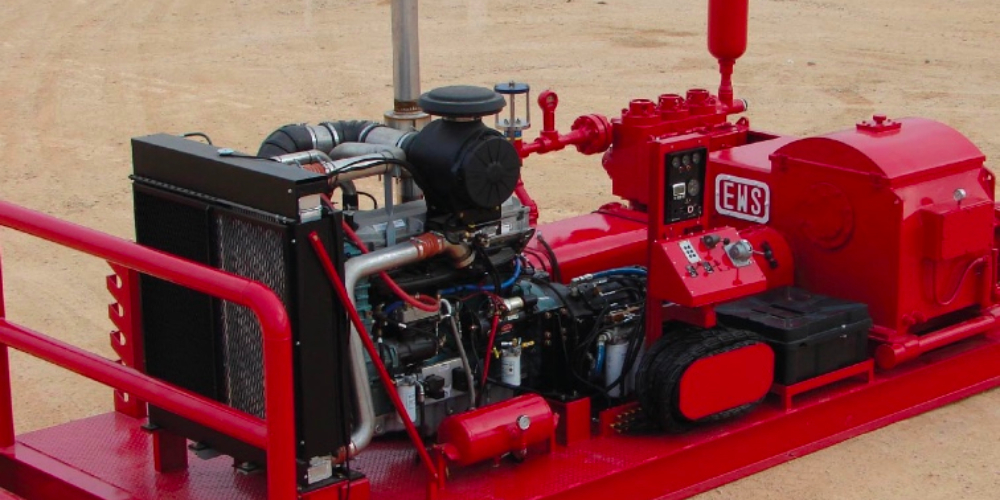

Mobile Workover Rigs | Dragon Products

Whether you need a well servicing rig, a drilling rig, workover rig, or mud pumps and systems, Dragon Products has you covered with reliable parts and exceptional service.

Oil Drilling Equipment FAQs

Below, we've answered some common questions about oil drilling equipment. Please let us know if you need additional information.

What Are the Main Stages of the Oil Drilling Process?

The oil drilling process involves several key stages: site preparation, spudding, drilling, casing and cementing, completion, and production. Each stage is critical to ensuring the successful extraction of oil and maintaining the integrity and safety of the well.

Why Is Rotary Drilling the Most Common Drilling Method?

Rotary drilling is the most common method due to its efficiency and adaptability to various geological conditions. It involves rotating a drill bit to create a wellbore and is capable of reaching significant depths, making it suitable for several drilling projects.

What Safety Measures Are in Place During Oil Drilling?

Oil drilling safety measures include using blowout preventers (BOPs), conducting regular equipment maintenance, and adhering to strict industry regulations and standards. These measures are designed to prevent accidents, protect workers, and minimize environmental impact.

How Does Directional Drilling Work?

Directional drilling involves controlling the direction of the wellbore to reach oil deposits that aren't directly beneath the drilling site. This technique is useful for accessing reservoirs located under obstacles or in areas where traditional vertical drilling isn't feasible.

Strike it Rich with the Best Oil Drilling Equipment from Dragon Products

Oil drilling is a sophisticated process that requires a deep understanding of the equipment and methods involved. By familiarizing yourself with the different types of oil drilling equipment and tools, you can optimize your operations and achieve successful oil extraction. Trust Dragon Products for superior oil drill rigs and equipment that stand the test of time.

CONTACT US

Sorry, the comment form is closed at this time.